Flange Management

Flange Management is the package of services that provides the best possible chance of achieving a leak-free tube&pipe connections. Correct assembly of a critical flange connection requires the highest quality in terms of machining and production of flanges. KRAIS Tube&Pipe Tools has a growing family of best tools for this kind of job!

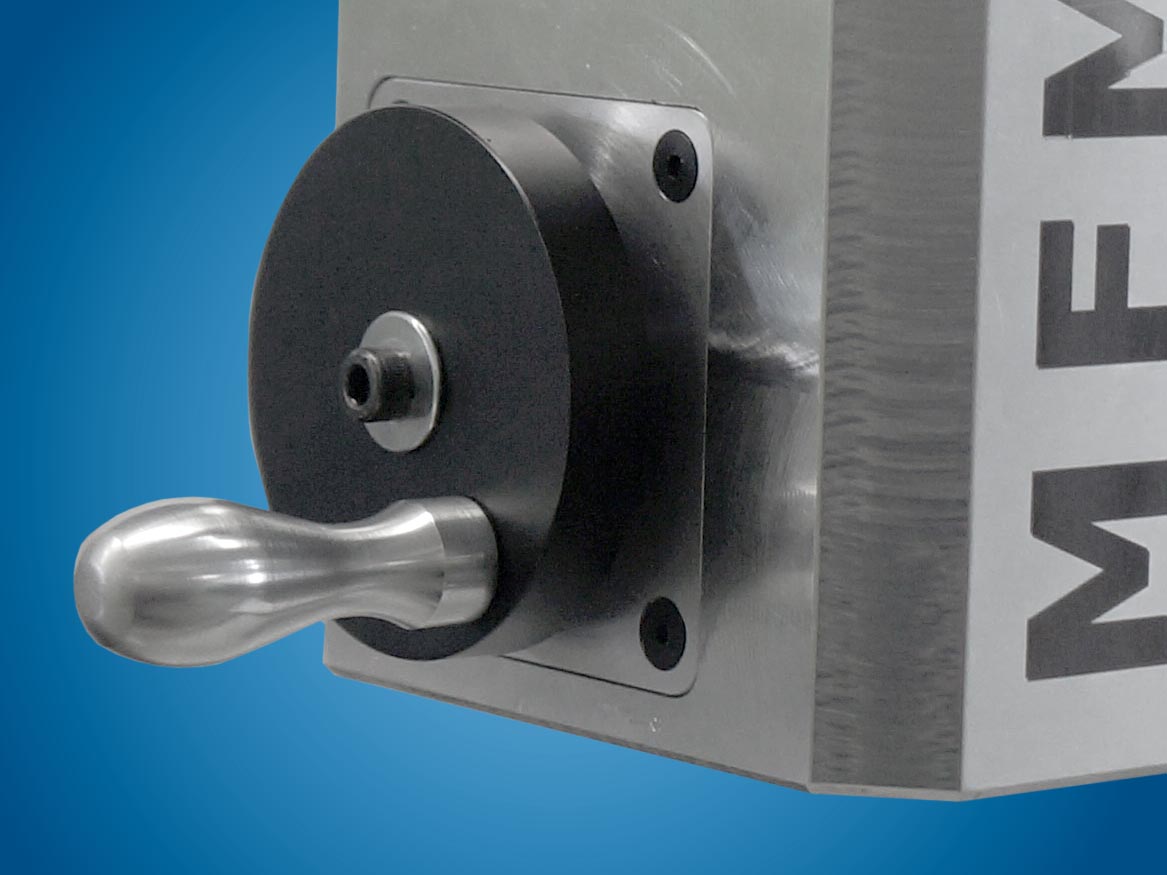

MFM – Manual FlangeMill

Inserts For Clamshells

Basic, simple and cost-effective solution for ID mount flange facing. It is a quick and easy way to reface a damaged flat, grooves in pipe flanges on site.

Manual FlangeMill size and body is designed and built to allow quick and convenient processing of small flanges in awkward or dangerous locations.

Manual FlangeMil comes in two versions: regular and long, see tables below!

Working range for regular version

| Facing Range | Locking Range | Max V Tool Travel | Max H Tool Travel | Body Swing Diameter |

|---|---|---|---|---|

| 30 – 350 mm | 25,4 – 254,0 mm | 10 mm | 55 mm | 457,2 mm |

| 1,75″ – 14,00″ | 1″ – 10″ | 0,395″ | 2,165″ | 18″ |

| Drive | Body width | Body height | Body weight |

|---|---|---|---|

| Manual | 165 mm | 325 mm | 8,8 kg |

| Manual | 6,5″ | 12,8″ | 19,4 Lbs |

Working range long version

| Facing Range | Locking Range | Max V Tool Travel | Max H Tool Travel | Body Swing Diameter |

|---|---|---|---|---|

| 51 – 650 mm | 51 – 550 mm | 10 mm | 55 mm | 757 mm |

| 2,01″ – 25,60″ | 2,01″ – 21,65″ | 0,395″ | 2,165″ | 30″ |

| Drive | Body width | Body height | Body weight |

|---|---|---|---|

| Manual | 165 mm | 475 mm | 8,8 kg |

| Manual | 6,5″ | 18,7″ | 19,4 Lbs |

Manual FlangeMill advantages

MACHINING IN EVERY POSITION

Manual FlangeMill can be freely rotated to work in every position. Remachining damaged flat, grooves and raised faced flanges on site is possible in every position.

EASE OF USE

The tool arm is rotated by hand using a worm-gear mechanism to provide a perfect spiral finish.