High-Speed Plate Beveling Machines

![]()

![]()

KBM Beveler

At Gullco International, we are a premier supplier of welding automation machines. We design and manufacture a wide range of equipment that helps improve product quality, process efficiency, and employee safety for our customers. One of our main product offerings is high-speed plate beveling machines. Learn more about our plate beveling machines by visiting out our online catalog.

What Do Plate Beveling Machines Do?

During welding operations, inadequate edge preparation can result in poor joint fit and, consequently, poor weld quality. That’s why fabrication facilities utilize plate beveling machines to prepare the material before it undergoes the welding process.

Plate beveling machines—also referred to as beveling machines or plate bevelers—employ shear blades to cut bevels onto the weld edges of plates. The bevels can be made to various angles depending on the assembly requirements of the final component or structure. This pre-welding treatment preps the weld edges to ensure accuracy and consistency, both of which are essential to achieving a quality weld. Additionally, it can also help decrease excessive welding, consumable waste, heat input, and labor requirements.

Plate bevelers find application in a wide range of metal fabrication projects. Examples of structures for which they are often used include ships, tanks, and windmills.

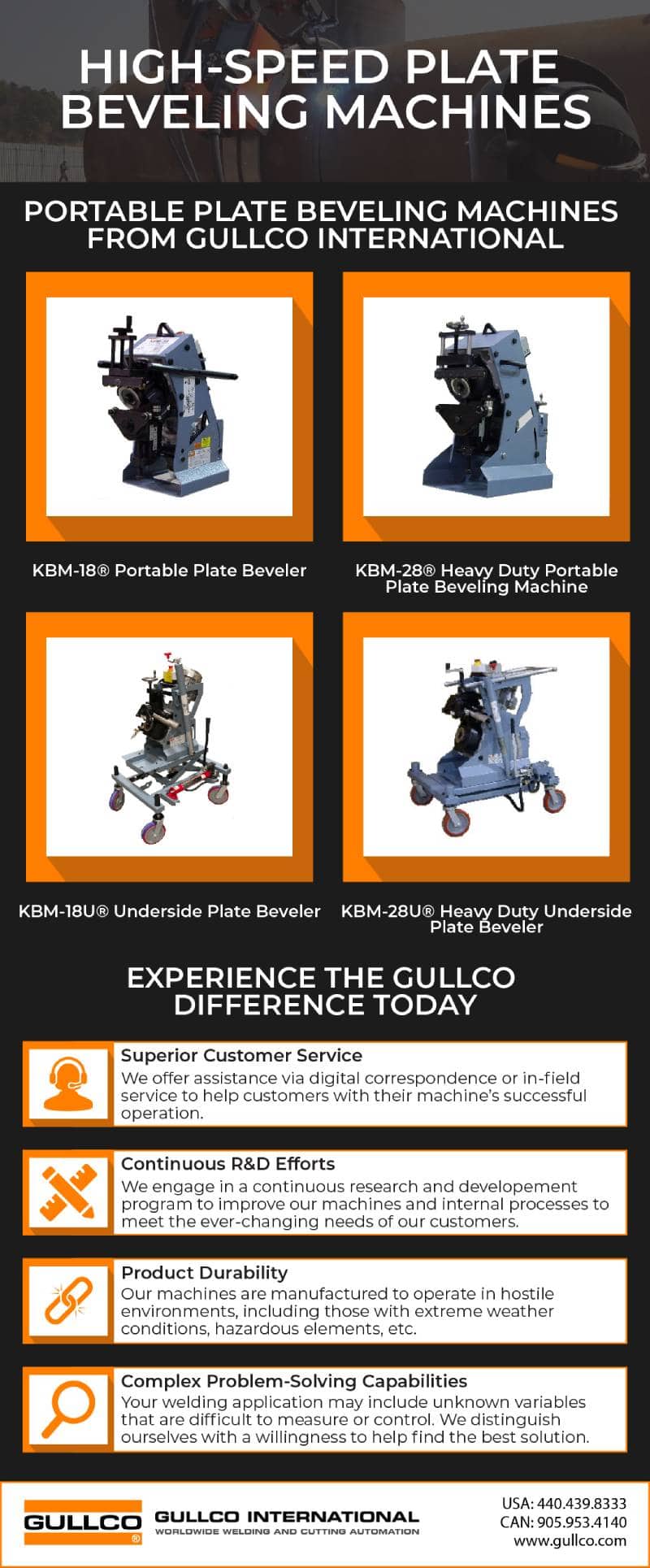

Portable Plate Beveling Machines From Gullco International

If you’re looking for portable beveling machines for your metal fabrication facility, Gullco International has got you covered. Our machine offerings include:

-

KBM-18® Portable Plate Beveler:

This self-propelled, portable unit produces clean edges without thermal distortion. It can produce topside bevels up to .71 in. (18 mm) wide and .65 in. (16.6 mm) deep on mild steel, stainless steel, aluminum, and other materials between 1/4 in. (6.0 mm) to 1 ½ in. (38.1 mm) thick as well as some thinner materials. An optional adjustable undercarriage makes height adjustments easy, allowing users to maintain a consistent root face and uniform bevel. It is often used in conjunction with KBM-18U for welding applications requiring beveling on both sides.

-

KBM-28® Heavy Duty Portable Plate Beveling Machine:

This heavy-duty, self-propelled, portable unit can produce topside bevels on materials between 5/16 in. (8.0 mm) to 2 in. (50.0 mm) thick. Similar to the KBM-18, it produces edges with no thermal distortion and can be purchased with an optional spring-loaded caster adjustable undercarriage. It is often used in conjunction with KBM-28U for welding applications requiring beveling on both sides.

-

KBM-18U® Underside Plate Beveler:

This self-propelled, portable beveling unit creates bevels on the underside of the plate. It also handles mild steel, stainless steel, aluminum, and other materials between 1/4 in. (6.0 mm) to 1 ½ in. (38.1 mm) thick as well as some thinner materials. It is often used in conjunction with KBM-18 for welding applications requiring beveling on both sides.

-

KBM-28U® Heavy Duty Underside Plate Beveler:

This heavy-duty, self-propelled, portable beveling unit creates bevels on the underside of the plate. It also handles materials between 5/16 in. (8.0 mm) to 2 in. (50.0 mm) thick. It is often used in conjunction with KBM-28 for welding applications requiring beveling on both sides.

Experience The Gullco Difference Today

Equipped with over 65 years of experience serving the welding industry, the experts at Gullco International have what it takes to manufacture top-of-the-line welding automation equipment for various metal fabrication needs, including plate bevelers. In addition to our extensive industry experience, by choosing us as your welding automation partner, you benefit from our:

- Superior Customer Service: We offer assistance via digital correspondence or in-field service to help customers with their machine’s successful operation.

- Continuous R&D Efforts: We never remain complacent. Instead, we engage in a continuous research and development program to improve our machines and internal processes to meet the ever-changing needs of our customers.

- Product Durability: Our machines are manufactured to operate in hostile environments, including those with extreme weather conditions, hazardous elements, etc.

- Complex Problem-Solving Capabilities: Your welding application may include unknown variables or other obstacles that are difficult to measure or control. We distinguish ourselves with a willingness to help find the best solution.

If you’re ready to take the next step in automating your welding processes, request a quote from our experts today.