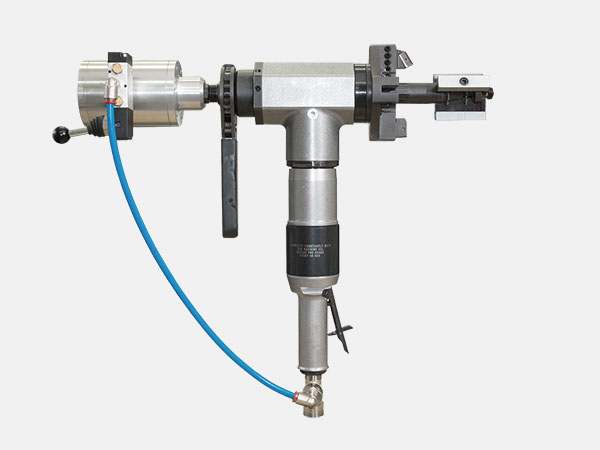

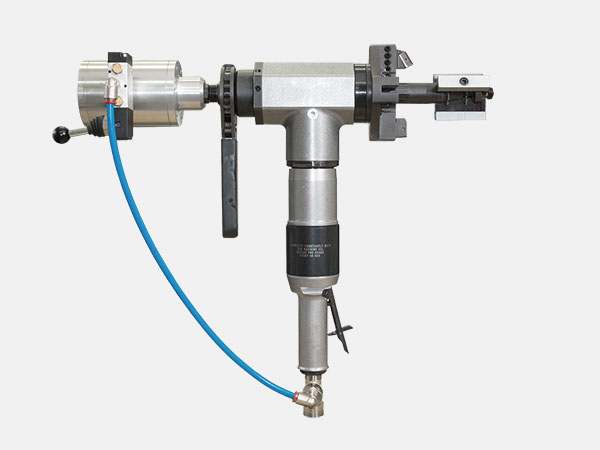

MiniMill 201

The MiniMill 201 is a rugged, fast, portable weld end preparation lathe for various tubes including stainless steel and other high chromium alloys. A standard machine comes complete with a 60 mm head, a locking system and includes all jaw sets to cover sizes of 20 to 44 mm (0.787” to 1.732”)

Standard working range

| APPLICATION RANGE | LOCKING RANGE (ID) |

| 12,5– 57,0 mm | 20,0 – 44,0 mm |

| 0,492 – 2,250” | 0,787 – 1,732” |

Motor parameters

| FEED STROKE | FREE SPEED | POWER | TORQUE | ||

| 20 mm | 0,787” | 200 Rpm | 1,3 Hp | 72 Nm | 53 Ft.Lbs |

| Air use: | 55 cfm | 1,3 m3/min | Body width: | 2,32” | 59 mm |

| Body height: | 13,1” | 335 mm | Body weight: | 11,4 Lbs | 5,2 kg |

Standard set up

SHAFTS 20 Redesigned heavy duty locking system. Shafts and jaws are longer and wider to ensure maximum clamping force. The jaws are self-align.

Redesigned heavy duty locking system. Shafts and jaws are longer and wider to ensure maximum clamping force. The jaws are self-align.

Redesigned heavy duty locking system. Shafts and jaws are longer and wider to ensure maximum clamping force. The jaws are self-align.

Redesigned heavy duty locking system. Shafts and jaws are longer and wider to ensure maximum clamping force. The jaws are self-align.60 MM (2,36”) The smallest cutter head, designed to fasten the wide range of cutting inserts.

The smallest cutter head, designed to fasten the wide range of cutting inserts.

The smallest cutter head, designed to fasten the wide range of cutting inserts.

The smallest cutter head, designed to fasten the wide range of cutting inserts.Optional heads

88 MM (3,46”) The popular, medium cutter head, designed to fasten the wide range of cutting inserts.

The popular, medium cutter head, designed to fasten the wide range of cutting inserts.

The popular, medium cutter head, designed to fasten the wide range of cutting inserts.

The popular, medium cutter head, designed to fasten the wide range of cutting inserts.OBMH Outside bevelling of both tubes and pipes. Sized per tube or pipe diameter and angle of required weld bevel.

Outside bevelling of both tubes and pipes. Sized per tube or pipe diameter and angle of required weld bevel.

Outside bevelling of both tubes and pipes. Sized per tube or pipe diameter and angle of required weld bevel.

Outside bevelling of both tubes and pipes. Sized per tube or pipe diameter and angle of required weld bevel.SWROTC Seal weld removal head over tube circumference prior to re-welding the damaged joint without removing the tube.

Seal weld removal head over tube circumference prior to re-welding the damaged joint without removing the tube.

Seal weld removal head over tube circumference prior to re-welding the damaged joint without removing the tube.

Seal weld removal head over tube circumference prior to re-welding the damaged joint without removing the tube.STWRMH Custom designed head dedicated for strength weld removal. Heads are sized per tube diameter.

Custom designed head dedicated for strength weld removal. Heads are sized per tube diameter.

Custom designed head dedicated for strength weld removal. Heads are sized per tube diameter.

Custom designed head dedicated for strength weld removal. Heads are sized per tube diameter.Optional shafts

MICROSHAFT A system with interchangeable guide shafts. A complete set covers 9,0 to 15,0 mm inside diameter.

A system with interchangeable guide shafts. A complete set covers 9,0 to 15,0 mm inside diameter.

A system with interchangeable guide shafts. A complete set covers 9,0 to 15,0 mm inside diameter.

A system with interchangeable guide shafts. A complete set covers 9,0 to 15,0 mm inside diameter.MINISHAFT A system with interchangeable guide shafts. A complete set covers 12,7 to 25 mm inside diameter.

A system with interchangeable guide shafts. A complete set covers 12,7 to 25 mm inside diameter.

A system with interchangeable guide shafts. A complete set covers 12,7 to 25 mm inside diameter.

A system with interchangeable guide shafts. A complete set covers 12,7 to 25 mm inside diameter.Additional accesories

SPEED REDUCER Easy to use gearbox for 3x speed reduction. Increases the torque, enabling the machine to generate a thick chip whilst reducing the cutting time.

Easy to use gearbox for 3x speed reduction. Increases the torque, enabling the machine to generate a thick chip whilst reducing the cutting time.

Easy to use gearbox for 3x speed reduction. Increases the torque, enabling the machine to generate a thick chip whilst reducing the cutting time.

Easy to use gearbox for 3x speed reduction. Increases the torque, enabling the machine to generate a thick chip whilst reducing the cutting time.SPEED ADJUSTMENT VALVE SAV-500 The solution for all pneumatic drove beveling machines. Allows adjusting cutting speed to suit to the machined tube diameter.

The solution for all pneumatic drove beveling machines. Allows adjusting cutting speed to suit to the machined tube diameter.

The solution for all pneumatic drove beveling machines. Allows adjusting cutting speed to suit to the machined tube diameter.

The solution for all pneumatic drove beveling machines. Allows adjusting cutting speed to suit to the machined tube diameter.FAST CLAMPING SYSTEM System offers rapid tube to tube cycle time, increased productivity (up to 4x) with little operator fatigue. Ideal for large amount of end preps.

System offers rapid tube to tube cycle time, increased productivity (up to 4x) with little operator fatigue. Ideal for large amount of end preps.

System offers rapid tube to tube cycle time, increased productivity (up to 4x) with little operator fatigue. Ideal for large amount of end preps.

System offers rapid tube to tube cycle time, increased productivity (up to 4x) with little operator fatigue. Ideal for large amount of end preps.LEVER FEED Quick and easy feed system. Used in many basic applications.

Quick and easy feed system. Used in many basic applications.

Quick and easy feed system. Used in many basic applications.

Quick and easy feed system. Used in many basic applications.RATCHET FEED Feed system allowing to work in narrow and tight locations, eg. in water walls.

Feed system allowing to work in narrow and tight locations, eg. in water walls.

Feed system allowing to work in narrow and tight locations, eg. in water walls.

Feed system allowing to work in narrow and tight locations, eg. in water walls.Bevelling Machines

- Tube & Pipe Beveling Machines

- ACTP-1000 Automatic set for tube pulling

- Auto MiniMill

- Beveling heads, inserts and cutters

- HyperLathe

- HyperMill 56

- HyperMill 76

- MWR Mini Wall Reducer

- MiniDril

- MiniLathe

- MiniMill 101

- MiniMill 201

- MiniMill 300FF

- MiniMill 300GFF

- MiniMill 301LP

- MWR-JGS Mini Grooving Tool

- PipeLathe 40

- PipeMill

- PrepMill

- SmartMill-7

- TES Mini 2

Rolling Controls

- Rolling & Expanding Tools

- Boiler Tube Expanders

- Condenser & Heat Exchangers Tube Expanders

- Rolling Motors

- Digital Controllers