MiniMill 300FF

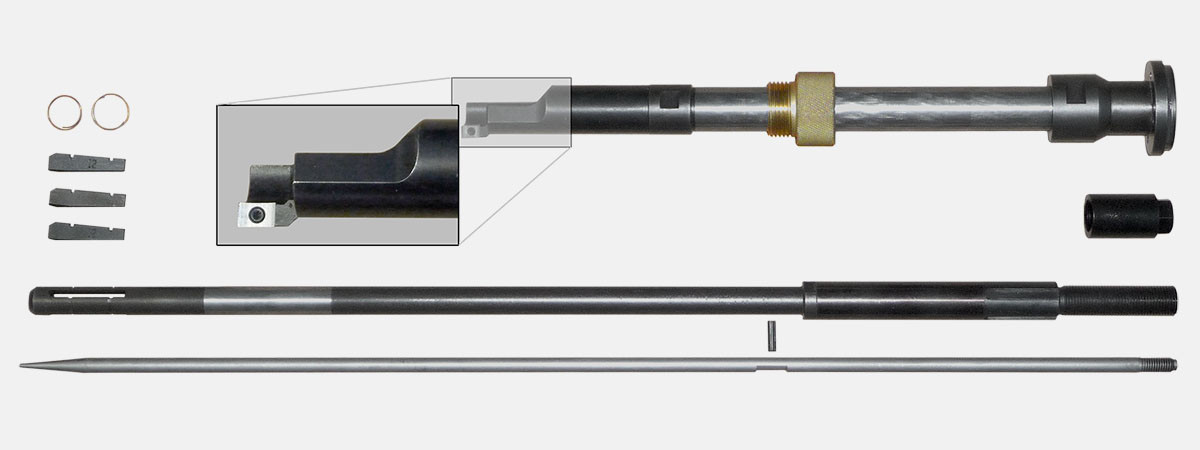

A standard machine for Fin Fan cooler tube trimming is equipped with custom head and locking system to suit your application (customer to provide drawing of unit).

The MiniMill 300FF cutter heads have 3 carbide inserts with 4 Cutting edges each.

Standard working range

| APPLICATION RANGE (ID-OD) | LOCKING RANGE (ID) |

| 12,5– 51,0 mm | Depends on attachment |

| 0,492 – 2,000” |

Motor parameters

| FEED STROKE | FREE SPEED | POWER | TORQUE | ||

| 20 mm | 0,787” | 300 Rpm | 1,3 Hp | 43 Nm | 32 Ft.Lbs |

| Air use: | 55 cfm | 1,3 m3/min | Body width: | 2,32” | 59 mm |

| Body height: | 13,1” | 335 mm | Body weight: | 13,2 Lbs | 6 kg |

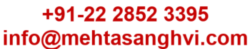

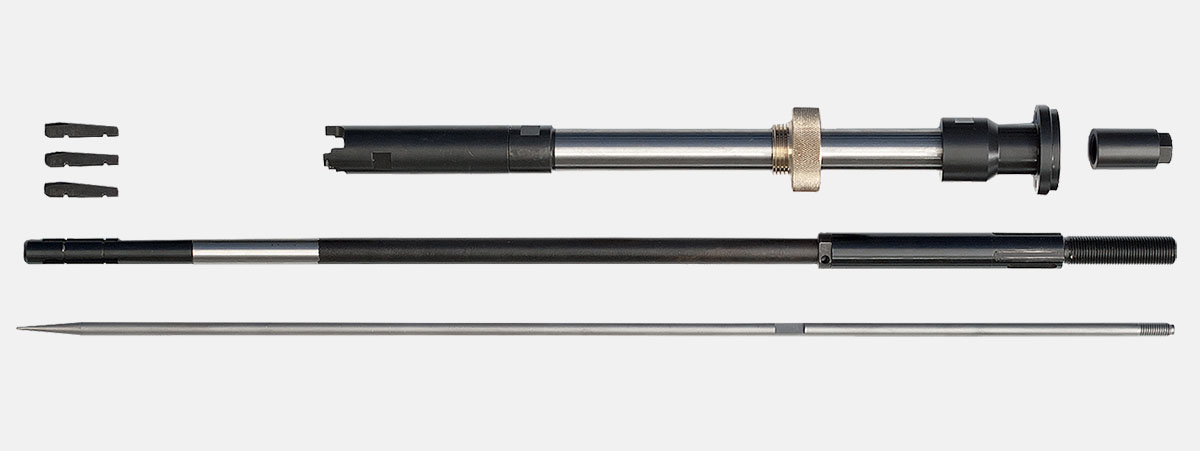

Standard set up

FINFAN ATTACHMENT Special attachment for facing tubes in fin fan gas coolers. A locking shaft with adjustable length and a support bushing are screwed into the plug thread, making this tool the best one available on the market today. The cycle is approx. 1 min from tube to tube. For this application we recommend our 300 Rpm machine.

Special attachment for facing tubes in fin fan gas coolers. A locking shaft with adjustable length and a support bushing are screwed into the plug thread, making this tool the best one available on the market today. The cycle is approx. 1 min from tube to tube. For this application we recommend our 300 Rpm machine.

Special attachment for facing tubes in fin fan gas coolers. A locking shaft with adjustable length and a support bushing are screwed into the plug thread, making this tool the best one available on the market today. The cycle is approx. 1 min from tube to tube. For this application we recommend our 300 Rpm machine.

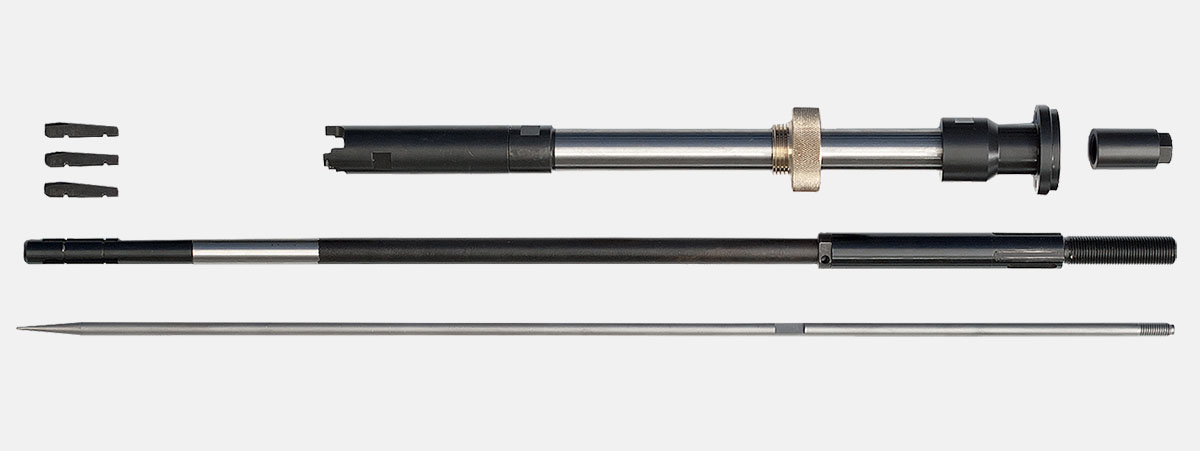

Special attachment for facing tubes in fin fan gas coolers. A locking shaft with adjustable length and a support bushing are screwed into the plug thread, making this tool the best one available on the market today. The cycle is approx. 1 min from tube to tube. For this application we recommend our 300 Rpm machine.FINFAN SEAL WELD REMOVAL ATTACHMENT Simply the best solution for seal weld removal from air coolers. Adjustable length locking shaft and support bushing that fits into the plug thread, making this tool the best one available on the market today. A cycle time of approximately 1 min from tube to tube can be expected.

Simply the best solution for seal weld removal from air coolers. Adjustable length locking shaft and support bushing that fits into the plug thread, making this tool the best one available on the market today. A cycle time of approximately 1 min from tube to tube can be expected.

Simply the best solution for seal weld removal from air coolers. Adjustable length locking shaft and support bushing that fits into the plug thread, making this tool the best one available on the market today. A cycle time of approximately 1 min from tube to tube can be expected.

Simply the best solution for seal weld removal from air coolers. Adjustable length locking shaft and support bushing that fits into the plug thread, making this tool the best one available on the market today. A cycle time of approximately 1 min from tube to tube can be expected.Additional accesories

SPEED REDUCER Easy to use gearbox for 3x speed reduction. Increases the torque, enabling the machine to generate a thick chip whilst reducing the cutting time.

Easy to use gearbox for 3x speed reduction. Increases the torque, enabling the machine to generate a thick chip whilst reducing the cutting time.

Easy to use gearbox for 3x speed reduction. Increases the torque, enabling the machine to generate a thick chip whilst reducing the cutting time.

Easy to use gearbox for 3x speed reduction. Increases the torque, enabling the machine to generate a thick chip whilst reducing the cutting time.SPEED ADJUSTMENT VALVE SAV-500 The solution for all pneumatic drove beveling machines. Allows adjusting cutting speed to suit to the machined tube diameter.

The solution for all pneumatic drove beveling machines. Allows adjusting cutting speed to suit to the machined tube diameter.

The solution for all pneumatic drove beveling machines. Allows adjusting cutting speed to suit to the machined tube diameter.

The solution for all pneumatic drove beveling machines. Allows adjusting cutting speed to suit to the machined tube diameter.LEVER FEED Quick and easy feed system. Used in many basic applications.

Quick and easy feed system. Used in many basic applications.

Quick and easy feed system. Used in many basic applications.

Quick and easy feed system. Used in many basic applications.Bevelling Machines

- Tube & Pipe Beveling Machines

- ACTP-1000 Automatic set for tube pulling

- Auto MiniMill

- Beveling heads, inserts and cutters

- HyperLathe

- HyperMill 56

- HyperMill 76

- MWR Mini Wall Reducer

- MiniDril

- MiniLathe

- MiniMill 101

- MiniMill 201

- MiniMill 300FF

- MiniMill 300GFF

- MiniMill 301LP

- MWR-JGS Mini Grooving Tool

- PipeLathe 40

- PipeMill

- PrepMill

- SmartMill-7

- TES Mini 2

Rolling Controls

- Rolling & Expanding Tools

- Boiler Tube Expanders

- Condenser & Heat Exchangers Tube Expanders

- Rolling Motors

- Digital Controllers